- Place of Origin:Hebei China (Mainland)

- Main Export Market:America, Europe, Australia, Mid-east, Africa, Asia

- Price:US $1,200 – 1,500 / Ton

- Price Valid Time:7 days

- Company Certificate:ISO 9001:2008,CE,SGS

- Quality Inspection:ISO 9001:2008,CE,SGS

- HS Code:7314490000

- Brand Name:DeChengli

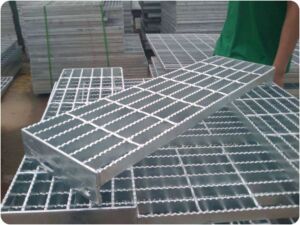

- Type:Steel Grating

- Material:S275JR,SS304,Mild steel & Low carbon steel,etc.

- Means of Transport:by sea

- Delivery Date:within 20 days

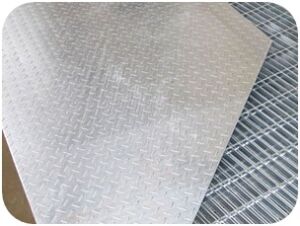

- Specification:Surface Treatment:Black,hot dip galvanized,painted,spray coating

- Applications:Steel plateform,steel structure,trench,etc.

- Packaging Detail:Normally packed in piling up ways with two pieces of square wood on both bottom sides. Also can be packed by customers’ requirements.

- Delivery Detail:within 30 days after formal order

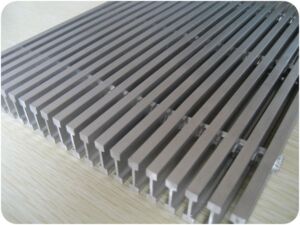

Material:fiberglass industrial plastic flooring is made of thoroughly wetted continuous glass strand fibers and a special resin that provides maximum corrosion resistance to chemicals.

Excellent:

(1).Safety:FRP is recommended when corrosion protection and safety are your goal.

(2).Stability:Expansion and contraction is 24% and 50% less than aluminum and steel, providing greater dimensional stability.

(3).Durability:Superior durability to Stainless Steel, Aluminum, and Galvanized Gratings, especially in highly corrosive environments.

(4).Strength:50%higher tensile strength than hot rolled steel and better impact resistance.

Surface Treatment:

Smooth surface grating,Concave surface grating, Microvoid grating, Sandy grating,Cover board gratin,Transparent grating.

a)Smooth surface and italic grid make it easy to clean.

b)Cross distributing loads equally to improve the bearing capacity.

c)Surface grooves prevent slipping, covered sand type is better in anti-slipping

Application:

They are widely used and according to their dimension they may be used as supporting and structural components in anti-corrosion and insulating applications, such as anti-corrosion work platforms, supporting of electrical cabinets, door and window frames, and decorative parts.

| Model No. | Mesh Size (mm) | Thickness (mm) | Full Panel Size (mm) | Open Area | Net Weight (Kg/m2) | Noted |

| WD-FG01 | 38*38 | 15 | 1262*3663 | 72 | 7.5 | |

| WD-FG02 | 50*50 | 15 | 1223*3663 | 65 | 6.5 | |

| WD-FG03 | 38*38 | 25 | 1223*3663 | 68.7 | 12.4 | |

| WD-FG04 | 100*25 | 25 | 1010*3010 | 65.7 | 12.4 | |

| WD-FG05 | 38*38 | 30 | 1223*4040 | 68.3 | 15.1 | |

| WD-FG06 | 19*19 | 30 | 1223*3663 | 39.6 | 21.5 | mini mesh |

| WD-FG07 | 38*38 | 35 | 1223*3663 | 66.1 | 17.8 | |

| WD-FG08 | 38*38 | 38 | 1223*3663 | 66.1 | 19.3 | |

| WD-FG09 | 19*19 | 38 | 1223*3663 | 39.6 | 22.8 | mini mesh |

| WD-FG10 | 40*40 | 40 | 1260*3690 | 69.6 | 19.3 | |

| WD-FG11 | 50*50 | 50 | 1223*3663 | 70.6 | 21.5 |

|

Maintenance:

1. Washing liquid can be used to clean the dust and dirties on the surface, no need of other maintenance measures.

2. Avoid direct connection with naked fire and high temperature, such as electric welding.

3. Avoid the drag and impact damage from any steel, steel sharp tools, and the painting pollution.